Developments in cement products

This article needs more work. To help develop this article click 'Edit this article' above.

Contents |

[edit] Introduction

Cement production has experienced significant development since it emerged some 2000 years ago. While the use of cement in concrete has a very long history, the industrial manufacturing of cements did not begin until the middle of 19th century with the development of chute kilns. These were later replaced by rotary kilns as the standard manufacturing equipment.

[edit] Development

While cement production has conventionally focused on Ordinary Portland Cement (OPC) composite and gustboiler slag cements, Portland pozzolanic cements and Portland limestone have also gained prominence, especially in areas where fly-ash or slag are not available.

Because of the global need to reduce CO2 emissions, and the drive for cost reduction, cement companies have attempted to lower the clinker content in their cements, although, there are limits which are given by cement performance. The decreasing of this clinker level in cement products is mainly taken into consideration in relation to the international accessibility of pozzolanic materials of industrial origin and latent hydraulic, a in particular there is a focus on cements products that have a high level of limestone content.This is essentially an extension of the present cement norms.

[edit] The requirement for new technologies

All cement products have to satisfy the basic requirements for strength development, durability, early strength development, cost, workability and environmental performance. Depending on the composition of the cement product, these requirements can be satisfied to different degrees. It lies with producers of these cements to optimise the differences in the types of products, and for the buyer to choose the suitable type for construction.

New cements products are likely to focus on durability capacity such as the penetration of chloride and carbonation resistance.

[edit] Future cements

There are a wide range of cement products available. Celitement for example, is founded on calcium silicate hybrid phases. Production is achieved by hydro-thermal mixture and by the reactive milling of lime in a silicon constituent. The Ca/Si ratio is lower when compared to OPC clinker, subsequently CO2 emissions and energy consumption might also be lower. However, it is presently too early to predict the future potential of these cements with respect to the production cost, strength or the practical potential for substitution of traditional cements.

Mark Long

[edit] Find out more

[edit] Related articles on Designing Buildings Wiki

- Aggregate.

- Alkali-aggregate reaction (AAR).

- Applications, performance characteristics and environmental benefits of alkali-activated binder concretes.

- Cement.

- Cement in Saudi Arabia.

- Coal ash.

- Concrete.

- Concreting plant.

- Efflorescence.

- High alumina cement.

- Material Flow Analysis: A tool for sustainable aggregate sourcing.

- Mortar.

- Rendering.

- Research on novel cements to reduce CO2 emissions.

- Screed.

- Stucco.

Featured articles and news

International Electrician Day, 10 June 2025

Celebrating the role of electrical engineers from André-Marie Amperè, today and for the future.

New guide for clients launched at Houses of Parliament

'There has never been a more important time for clients to step up and ...ask the right questions'

The impact of recycled slate tiles

Innovation across the decades.

EPC changes for existing buildings

Changes and their context as the new RdSAP methodology comes into use from 15 June.

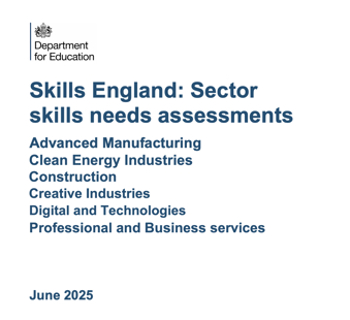

Skills England publishes Sector skills needs assessments

Priority areas relating to the built environment highlighted and described in brief.

BSRIA HVAC Market Watch - May 2025 Edition

Heat Pump Market Outlook: Policy, Performance & Refrigerant Trends for 2025–2028.

Committing to EDI in construction with CIOB

Built Environment professional bodies deepen commitment to EDI with two new signatories: CIAT and CICES.

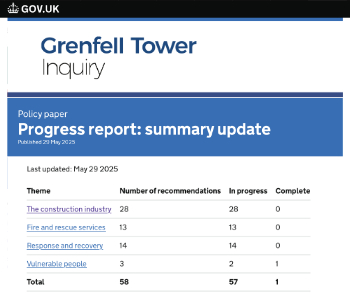

Government Grenfell progress report at a glance

Line by line recomendation overview, with links to more details.

An engaging and lively review of his professional life.

Sustainable heating for listed buildings

A problem that needs to be approached intelligently.

50th Golden anniversary ECA Edmundson apprentice award

Deadline for entries has been extended to Friday 27 June, so don't miss out!

CIAT at the London Festival of Architecture

Designing for Everyone: Breaking Barriers in Inclusive Architecture.

Mixed reactions to apprenticeship and skills reform 2025

A 'welcome shift' for some and a 'backwards step' for others.

Licensing construction in the UK

As the latest report and proposal to licence builders reaches Parliament.

Building Safety Alliance golden thread guidance

Extensive excel checklist of information with guidance document freely accessible.

Fair Payment Code and other payment initiatives

For fair and late payments, need to work together to add value.

Pre-planning delivery programmes and delay penalties

Proposed for housebuilders in government reform: Speeding Up Build Out.

High street health: converting a building for healthcare uses

The benefits of health centres acting as new anchor sites in the high street.